Mumakore achangopfuura, pane kukurumidza kukura kwefiber-reinforcedthermoplastic composites ne thermoplastic resins sematrix, uye kune kuwedzera kwekutsvaga nekuvandudzwa kweaya epamusoro-performance composite pasi rose. Thermoplastic composites inoumbwa ne thermoplastic mapolymers akadai se polyethylene (PE), polyamide (PA), polyphenylene sulfide (PPS), polyetherimide (PEI), polyether ketone (PEKK) uye polyether ether ketone (PEEK) sematrix uye zvakasiyana-siyana zvinoramba zvichienderera mberi. mafibers (eg carbon fibers, glass fibers, aramid fibers, etc.

Thermoplastic grease-based composites inonyanya kuLong Fiber yakasimbiswa Thermoplastics (LFT), MT inoenderera mberi-yakaiswa pre-impregnated matepi uye girazi mat yakasimbiswa Thermoplastics(CMT).

Maererano nekushandiswa kwezvinodiwa zvakasiyana, resin matrix ine PPE.PAPRT, PELPCPES, PEEKPI, PA uye mamwe thermoplastic engineering mapurasitiki.

Thermoplastic matrix

Thermoplastic matrix imhando ye thermoplastic material ine yakanaka mechaniki zvivakwa uye kupisa kupisa kunogona kushandiswa mumhando dzakasiyana dzezvigadzirwa zvemaindasitiri. Thermoplastic matrix ine simba rakawanda, kupisa kwekudzivirira uye kunaka kwekusagadzikana.

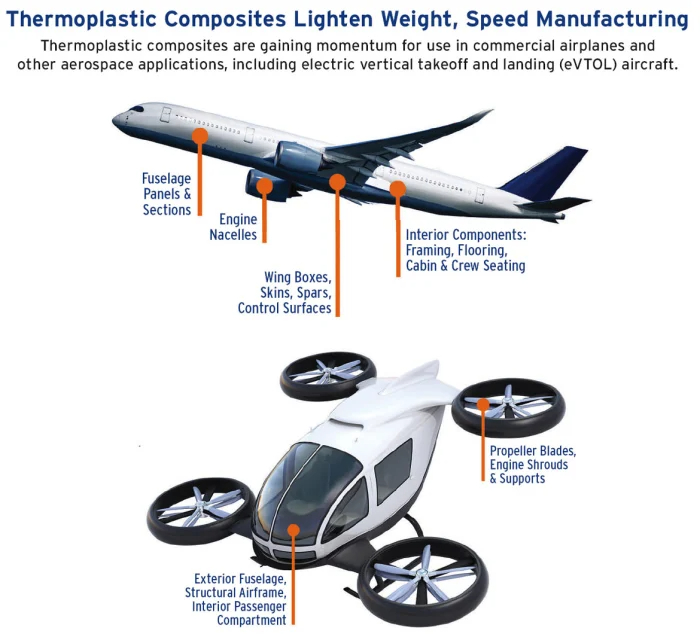

Iwo thermoplastic resins anoshandiswa pari zvino muaerospace application anonyanya kupisa-tembiricha, akakwira-performance resin matrices, anosanganisira PEEK, PPS uye PEI, ayo amorphous PEI inonyanya kushandiswa muaerospace application pane semi-crystalline PPS nePEEK, iyo amorphous PEI. ine mamwe maapplication muzvimiro zvendege kupfuura semi-crystalline PPS uye yakakwirira yekuumbwa tembiricha PEEK nekuda kwekudzikira kwayo kupisa tembiricha uye mutengo wekugadzirisa.

Thermoplastic resins ine zvirinani zvemuchina uye makemikari kuramba, yakakwirira sevhisi tembiricha, yakakwirira chaiyo kusimba uye kuoma, yakanakisa kuputsika kusimba uye kushivirira kwekukuvara, kwakanyanya kuneta kuramba, kugona kuumba yakaoma geometri uye zvimiro, inogadziriswa yekupisa conductivity, kudzokorodza, kugadzikana kwakanaka munzvimbo dzakaoma. , inodzokororwa kuumbwa, uye weldability, nezvimwe.

Composites inoumbwa ne thermoplastic resin uye inosimbisa zvinhu ine zvakawanda zvakanaka sekugara kwenguva refu, kusimba kwepamusoro, kukwirira kwesimba uye kushivirira kwekukuvara; fiber prepreg haidi kuchengetwa pane yakaderera tembiricha zvakare, isina muganho prepreg yekuchengetedza nguva; pfupi kuumbwa kutenderera, weldable, yakakwirira kugadzirwa, nyore kugadzirisa; zvimedu zvinogona kushandiswazve uye kushandiswazve; Rusununguko rwakakura rwekugadzirwa kwechigadzirwa, rinogona kugadzirwa kuita maumbirwo akaomarara, yakafara molding kuchinjika, nezvimwe.

Kusimbisa zvinhu

Kazhinji, kureba kwefiber mapfupi akasimbisa fibers ndeye 0.2 kusvika 0.6 mm, uye sezvo mafiber akawanda ari pasi pe70 μm muhupamhi, saka mafupi mafiber anotarisa zvakanyanya seupfu. Short fiber reinforced thermoplastics inowanzogadzirwa nekusanganisa faibha kuita yakanyungudutswa thermoplastics. Kureba uye kurongeka kwemafiber ari mumatrix kunoita kuti zvive nyore kuwana kunyorova kwakanaka, uye mapfupi fiber composites ndiwo ari nyore kugadzira kana achienzaniswa neakareba uye anoenderera mberi fiber yakasimbiswa zvinhu, asi nekunatsiridza kushoma kwezvinhu zvemakanika. Mapfupi faibha macomposites anowanzo kuumbwa kuita zvikamu zvekupedzisira nekuumbwa kana nzira dzekuwedzera nekuti mapfupi fiber ane simba shoma pakuyerera.

Yakareba fiber yakasimbiswa composites anowanzo svika 20 mm mukureba kwefayibha uye anowanzo gadzirirwa achishandisa tambo dzinoramba dzichipinzwa neresin uye dzocheka kune imwe urefu. Maitiro anowanzo shandiswa ndeye pultrusion molding process, umo inoenderera ichitenderera yemusanganiswa wefiber uye thermoplastic resin inogadzirwa nekutambanudza mafibhi kuburikidza neakakosha ekuumba kufa. Parizvino, refu fiber-yakasimbiswa PEEK thermoplastic composites inogona kuwana zvimiro zveanopfuura mazana maviri MPa kuburikidza neFDM kudhinda uye modulus inodarika makumi maviri GPa, nekuita zvirinani kuburikidza nekuumbwa kwejekiseni.

Mafayibha ari muinoenderera mberi fiber reinforced composites "anoenderera" uye anoreba kubva pamamita mashoma kusvika kune akati wandei mamita. Inoenderera mberi fiber macomposites anowanzo kuwanikwa se laminates, prepreg matepi, kana mabraids, akaumbwa nekumisikidza inodiwa thermoplastic matrix ine inoenderera fibers.

Ndeapi maitiro ezvakasanganiswa zvinhu zvakasimbiswa nefiber?

Fiber yakasimbiswa macomposites maumbirwo anoumbwa nekumonereka, kuumba kana pultrusion maitiro ekusimbisa fiber zvinhu, senge girazi fiber, kabhoni fiber, aramid fiber, nezvimwewo, uye matrix zvinhu. Zvinoenderana neakasiyana ekusimbisa zvinhu, akajairwa faibha-yakasimbiswa macomposites akakamurwa kuita girazi fiber reinforced composites (GFRP), kabhoni fiber reinforced composites (CFRP) uye aramid fiber reinforced composites (AFRP).

Nekuda kweanotevera maitiro efiber-reinforced composites:

(1) simba rakakwirira uye yakakwirira modulus;

(2) designability yezvinhu;

(3) kunaka kwekudzivirira uye kusimba;

(4) coefficient yekuwedzera kwekushisa kwakafanana neyekongiri.

Aya maitiro anoitaFRP zvinhuinogona kusangana nezvinodiwa zvezvivakwa zvemazuva ano kusvika pahombe, shongwe, mutoro unorema, huremu huremu uye simba rakawanda, uye kushanda pasi pemamiriro akaomarara, uye zvakare kusangana nezvinodiwa zvekuvandudzwa kwezvivakwa zvemazuva ano zvemaindasitiri ekuvaka zvivakwa, saka zviri kuwedzera uye zvakanyanya kushandiswa. muzvivakwa zvakasiyana-siyana zvevagari, mabhiriji, migwagwa mikuru, marine, hydraulic zvimiro uye zvimiro zvepasi pevhu.

Dzvanya panokuti uwane rumwe ruzivo nezve composite zvinhu nezveGRECHO Fiberglass

Nguva yekutumira: Mar-31-2023